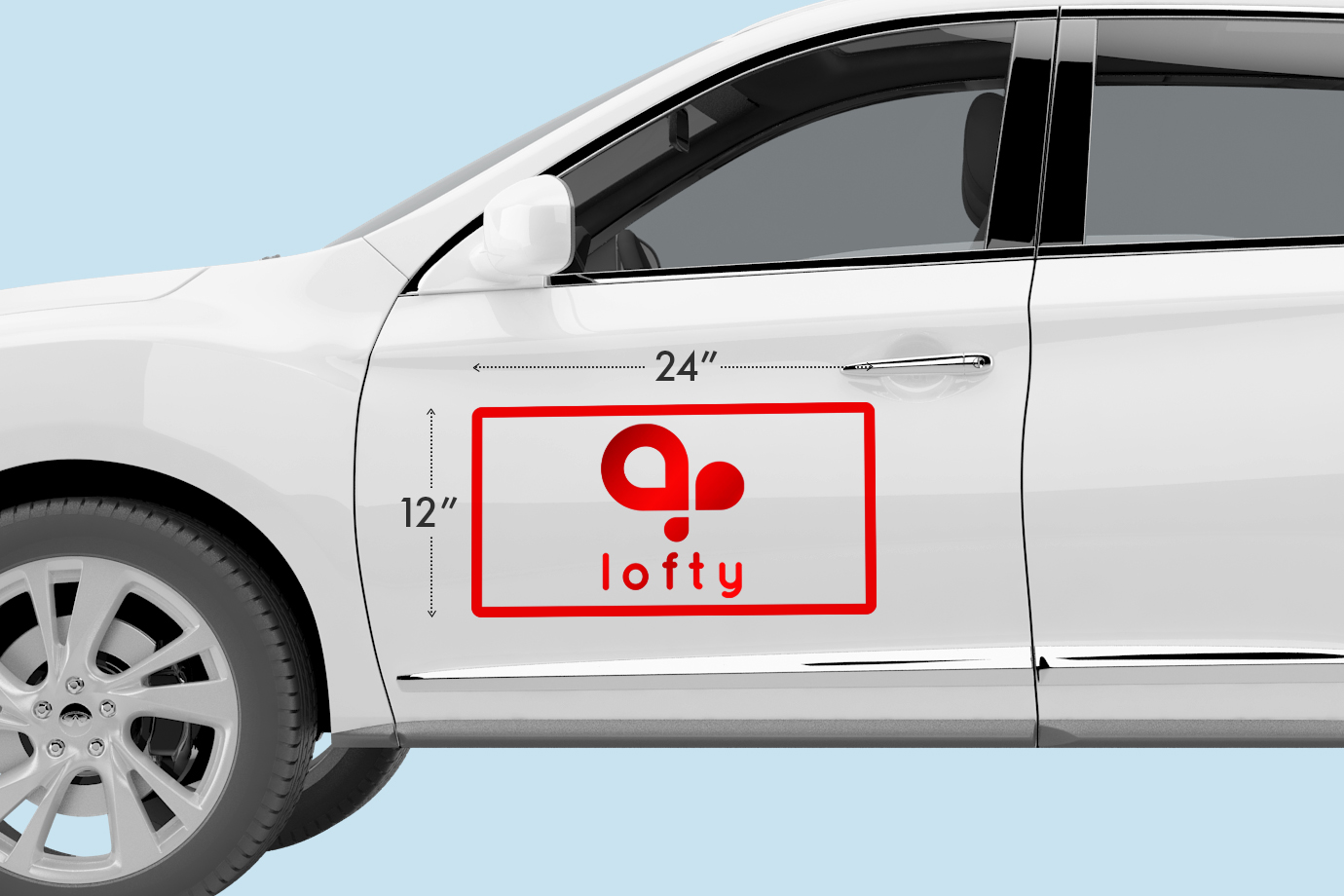

A vinyl lettering sticker is an adhesive label made from vinyl material, cut into custom letters or numbers, used for signage, decoration, and branding on various surfaces. Choose from our standard sizes, each offering its own canvas for creativity

A vinyl lettering sticker is an adhesive label made from vinyl material, cut into custom letters or numbers, used for signage, decoration, and branding on various surfaces. Choose from our standard sizes, each offering its own canvas for creativityHow to choose the perfect fit?

If you have an artwork, check the size using Adobe Acrobat's 'Check Document Property' feature; find more info here If you do not have an Artwork file ready, feel free to use any one of the templates provided for the standard sizes. This product offers no printing of any artwork. Our product now offers a wide range of color materials for you to choose from.

This product offers no printing of any artwork. Our product now offers a wide range of color materials for you to choose from.Which color sticker should I choose?

Our meticulously handpicked selection of colors is here to serve your every need. We have a range from bright colors like red and yellow to a duller, more subtle color such as grey. Or you require something more robust or premium, you can always go for our Matte silver or gold color Explore our reflective color sticker materials, each uniquely tailored to cater to your specific needs and preferences.

Explore our reflective color sticker materials, each uniquely tailored to cater to your specific needs and preferences.Which material should I choose?

Discover our range of sticker materials tailored to your needs. Our Reflective Color Stickers feature a glossy, reflective surface that enhances vibrancy and visibility, perfect for both indoor and outdoor use. Elevate your creations and make a lasting impression today. We offer Standard and Reverse cut stickers.

We offer Standard and Reverse cut stickers.Which cut to choose?

A standard cut sticker is perfect for your sticker if you wish to apply it on the inside of the window and read from the inside. While a reverse cut, is meant for the sticker to be applied on the inside of the window but read from the outside.Choose a Quantity & Delivery Date

Please select the price below to see the cutoff time. | ||||

| Quantities | Get It By Tue, 6 Aug | Get It By Wed, 7 Aug | Get It By Thu, 8 Aug | Get It By Fri, 9 Aug |

| 1 pcs | ||||

| 2 pcs | ||||

| 3 pcs | ||||

| 5 pcs | ||||

| 10 pcs | ||||

| 20 pcs | ||||

| 50 pcs | ||||

| 100 pcs | ||||

Can't find the quantity you're looking for? You can add a custom quantity you want Set Custom Quantity | ||||